how do skid steer hydraulics work For the skid steer loader, each side of the machine is powered by a hydraulic motor. Each of the two motors (one for each side) connects to a sprocket, and each sprocket is connected by two . This is a new 24″ tooth trench bucket for a Bobcat mini excavator with the quick attach mounting system. This particular bucket is designed for all E Series models as well as the new style models with the pins for Bobcat models 325, 328, 331, 334, 337, 341, 430, and 435 with the Quick X Change mount.These buckets are for compact or mini excavators. Mini excavators are defined on Wikipedia .

0 · what is a skid loader

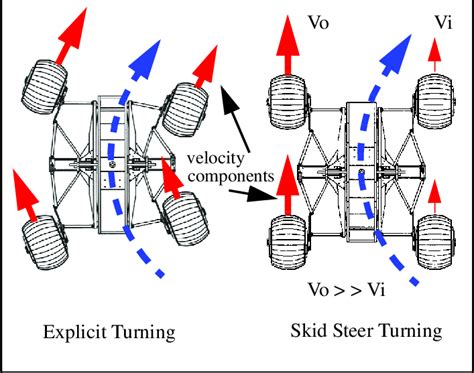

1 · skid steering drive

2 · skid steer work needed

3 · skid steer work near me

4 · skid steer operator jobs

5 · skid steer loader uses

6 · skid steer loader definition

7 · skid steer lift capacity

You can rent a mini-excavator for between $475 to $675 a day on average, and between $3,575 to $4,800 a month. Here is a quick list of the average rental price for popular mini-excavator models.

Rob from [https://www.skidsteersolutions.com/accessories/hydraulic-couplers] covers the topic of Skid Steer hydraulics and how they work. Rob has over 25 . Learn how the hydrostatic closed circuit drive system and load sensing ancillaries work in a typical skid-steer machine. This video shows how our skidsteer simulation provides a number of.For the skid steer loader, each side of the machine is powered by a hydraulic motor. Each of the two motors (one for each side) connects to a sprocket, and each sprocket is connected by two . A standard-flow system powers many of the most common hydraulic attachments on the market, such as 4-in-1 buckets, hydraulic hammers, augers, trenchers and grapples. A .

what is a skid loader

skid steering drive

Learn about the different types and configurations of hydraulic pumps and systems in skid steers and track loaders, and how to properly maintain them. Find out the . Learn the basics and nuances of auxiliary hydraulics systems on skid steers and compact track loaders, and how to choose the right attachments based on pressure, flow and .These arms and their associated hydraulics are designed to hold a variety of implements, not just buckets. The lifting capability of the arms is carefully matched with the rest of the machine so .

On a skid steer loader or multi terrain loader, an engine at full speed can produce its top rated horsepower. Between the pumps that power the wheels and the pump that powers the work .

When operating a skid steer there are typically two types of hydraulic systems that are available: high-flow hydraulics and standard-flow hydraulics. Each has its specific functions . The majority of controls today work off hydraulics — electro-hydraulic and pilot-hydraulic — both of which are available in two operating patterns (H and ISO). “Pilot controls use low pressure hydraulics to shift the valves spools,” says Nathan Ryan, global product manager at .Rob from [https://www.skidsteersolutions.com/accessories/hydraulic-couplers] covers the topic of Skid Steer hydraulics and how they work. Rob has over 25 yea.

tree mulching skid steer

skid steer work needed

universal skid steer coupler

Learn how the hydrostatic closed circuit drive system and load sensing ancillaries work in a typical skid-steer machine. This video shows how our skidsteer simulation provides a number of.For the skid steer loader, each side of the machine is powered by a hydraulic motor. Each of the two motors (one for each side) connects to a sprocket, and each sprocket is connected by two chains to each wheel. A standard-flow system powers many of the most common hydraulic attachments on the market, such as 4-in-1 buckets, hydraulic hammers, augers, trenchers and grapples. A high-flow auxiliary hydraulics system is a second option that further increases a skid steer’s versatility and productivity. Learn about the different types and configurations of hydraulic pumps and systems in skid steers and track loaders, and how to properly maintain them. Find out the specifications, specifics and tips for each brand and model.

Learn the basics and nuances of auxiliary hydraulics systems on skid steers and compact track loaders, and how to choose the right attachments based on pressure, flow and hydraulic horsepower. CASE product managers explain the differences between standard, high-flow and enhanced high-flow systems, and offer tips for optimal performance and productivity.

These arms and their associated hydraulics are designed to hold a variety of implements, not just buckets. The lifting capability of the arms is carefully matched with the rest of the machine so that the operator lifts the load, not the machine.On a skid steer loader or multi terrain loader, an engine at full speed can produce its top rated horsepower. Between the pumps that power the wheels and the pump that powers the work tools, the hydraulic system can demand more power from the engine than the engine can generate. When operating a skid steer there are typically two types of hydraulic systems that are available: high-flow hydraulics and standard-flow hydraulics. Each has its specific functions so it's essential to know the differences, what attachments they're compatible with, and .

The majority of controls today work off hydraulics — electro-hydraulic and pilot-hydraulic — both of which are available in two operating patterns (H and ISO). “Pilot controls use low pressure hydraulics to shift the valves spools,” says Nathan Ryan, global product manager at .Rob from [https://www.skidsteersolutions.com/accessories/hydraulic-couplers] covers the topic of Skid Steer hydraulics and how they work. Rob has over 25 yea. Learn how the hydrostatic closed circuit drive system and load sensing ancillaries work in a typical skid-steer machine. This video shows how our skidsteer simulation provides a number of.

skid steer work near me

For the skid steer loader, each side of the machine is powered by a hydraulic motor. Each of the two motors (one for each side) connects to a sprocket, and each sprocket is connected by two chains to each wheel.

A standard-flow system powers many of the most common hydraulic attachments on the market, such as 4-in-1 buckets, hydraulic hammers, augers, trenchers and grapples. A high-flow auxiliary hydraulics system is a second option that further increases a skid steer’s versatility and productivity.

Learn about the different types and configurations of hydraulic pumps and systems in skid steers and track loaders, and how to properly maintain them. Find out the specifications, specifics and tips for each brand and model.

Learn the basics and nuances of auxiliary hydraulics systems on skid steers and compact track loaders, and how to choose the right attachments based on pressure, flow and hydraulic horsepower. CASE product managers explain the differences between standard, high-flow and enhanced high-flow systems, and offer tips for optimal performance and productivity.These arms and their associated hydraulics are designed to hold a variety of implements, not just buckets. The lifting capability of the arms is carefully matched with the rest of the machine so that the operator lifts the load, not the machine.On a skid steer loader or multi terrain loader, an engine at full speed can produce its top rated horsepower. Between the pumps that power the wheels and the pump that powers the work tools, the hydraulic system can demand more power from the engine than the engine can generate.

truss lift for skid steer

**Unused Manufacturer Consignment** Engine: Briggs & Stratton 410cc Gas Transmission: Hydrostatic 16" dig bucket, thumb, auxiliary hydraulics, 36 1/2" push blade, LED work light, ROPS, canopy,.

how do skid steer hydraulics work|skid steer operator jobs