osha skid steer regulations This letter explains the training requirements for skid-steer loaders used for . Browse a wide selection of new and used CATERPILLAR 305E CR Excavators for sale near you at MachineryTrader.com

0 · skid steer safe operating procedure

1 · osha regulations on skid steer

2 · osha regulations 1926.602

3 · osha heavy equipment inspection requirements

4 · osha forklift seat belt requirements

5 · osha certification for skid steer

6 · osha 1926 powered industrial trucks

7 · free skid steer certification online

Find the best rubber tracks for your mini excavator from McLaren, America's #1 rubber track manufacturer. Choose from NextGen, Maximizer, or HYBRID series tracks with different tread .

Learn about the safety and health standards for earthmoving equipment, such as scrapers, loaders, tractors, and bulldozers, in construction. Find out the requirements for seat belts, brakes, fenders, rollover protective structures, and audible alarms.

Find Training on Many Topics. The OSHA Training Institute (OTI) Education Centers are a n.

skid steer safe operating procedure

osha regulations on skid steer

The site is secure. The https:// ensures that you are connecting to the official website and th. This letter explains the training requirements for skid-steer loaders used for .Learn about the safety and health standards for earthmoving equipment, such as scrapers, loaders, tractors, and bulldozers, in construction. Find out the requirements for seat belts, brakes, fenders, rollover protective structures, and audible alarms. This letter explains the training requirements for skid-steer loaders used for earthmoving in construction, based on 29 CFR 1910.178 and 1926.602. It also clarifies the meaning of "qualified by experience" and the difference between training and instruction.

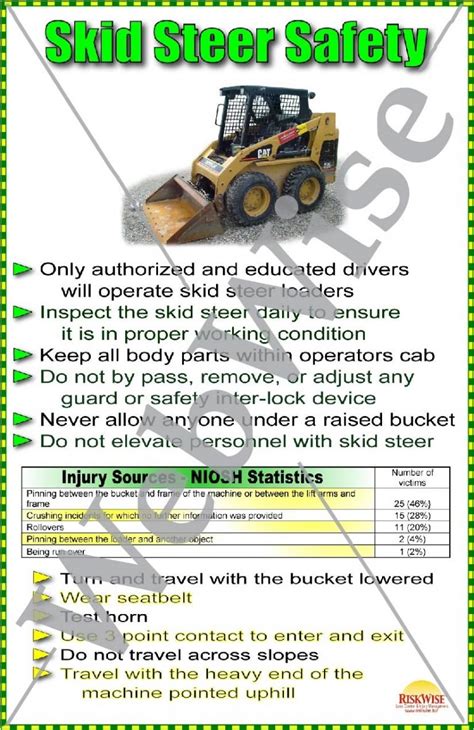

Find the requirements for seat belts, brakes, fenders, ROPS, and audible alarms for earthmoving equipment in 29 CFR 1926.602. The web page also has a specific rule for reverse signal alarm or employee signal for equipment with obstructed view.This bulletin warns about the dangers of bypassing or improperly maintaining safety devices on skid-steer loaders, such as seatbelts, interlocks, and FOPS. It cites three fatal accidents caused by these practices and provides recommendations for employers and employees.This document provides safety tips and warnings for workers who operate or work near skid-steer loaders. It covers topics such as safe operating procedures, entering and exiting the loader, maintaining the machine, and avoiding hazards. Learn about the risks and injuries associated with skid-steer loaders, a versatile machine used for various applications. Find out how to comply with OSHA standards and follow universal safety features and recommended practices to prevent accidents.

OSHA’s Code of Federal Regulations Subpart C “General Safety And Health” provisions require skid-steer operators to be trained under CFR 1926.21(b)(2) and CFR 1926.20(b)(4) requirements. The employer is required to train skid-steer operators so .This course provides thorough instruction on machine operation, risk assessment, and maintenance procedures, aligned with current OSHA regulations. Gain the confidence and certification you need to operate skid steers safely, backed by the latest best practices in the field.This section prescribes minimum performance criteria for roll-over protective structures (ROPS) for rubber-tired self-propelled scrapers; rubber-tired front end loaders and rubber-tired dozers; crawler tractors and crawler-type loaders, motor graders, .

Skid Steer OSHA Training Requirements. As with forklifts, OSHA requires operators of skid steer loaders to be trained. Its regulation OSHA CFR 1926.21 states:Learn about the safety and health standards for earthmoving equipment, such as scrapers, loaders, tractors, and bulldozers, in construction. Find out the requirements for seat belts, brakes, fenders, rollover protective structures, and audible alarms. This letter explains the training requirements for skid-steer loaders used for earthmoving in construction, based on 29 CFR 1910.178 and 1926.602. It also clarifies the meaning of "qualified by experience" and the difference between training and instruction.

Find the requirements for seat belts, brakes, fenders, ROPS, and audible alarms for earthmoving equipment in 29 CFR 1926.602. The web page also has a specific rule for reverse signal alarm or employee signal for equipment with obstructed view.This bulletin warns about the dangers of bypassing or improperly maintaining safety devices on skid-steer loaders, such as seatbelts, interlocks, and FOPS. It cites three fatal accidents caused by these practices and provides recommendations for employers and employees.This document provides safety tips and warnings for workers who operate or work near skid-steer loaders. It covers topics such as safe operating procedures, entering and exiting the loader, maintaining the machine, and avoiding hazards. Learn about the risks and injuries associated with skid-steer loaders, a versatile machine used for various applications. Find out how to comply with OSHA standards and follow universal safety features and recommended practices to prevent accidents.

osha regulations 1926.602

OSHA’s Code of Federal Regulations Subpart C “General Safety And Health” provisions require skid-steer operators to be trained under CFR 1926.21(b)(2) and CFR 1926.20(b)(4) requirements. The employer is required to train skid-steer operators so .This course provides thorough instruction on machine operation, risk assessment, and maintenance procedures, aligned with current OSHA regulations. Gain the confidence and certification you need to operate skid steers safely, backed by the latest best practices in the field.This section prescribes minimum performance criteria for roll-over protective structures (ROPS) for rubber-tired self-propelled scrapers; rubber-tired front end loaders and rubber-tired dozers; crawler tractors and crawler-type loaders, motor graders, .

osha heavy equipment inspection requirements

osha forklift seat belt requirements

osha certification for skid steer

osha 1926 powered industrial trucks

Find the key specifications of the 335 Compact Excavator, a non-current model produced in 2008. See operating weight, bucket digging force, maximum reach, tail swing type, and more.

osha skid steer regulations|osha heavy equipment inspection requirements