mathematical model skid steer In this section kinematic and dynamic model of four-wheel skid-steering mobile robot is .

Find new and used mini excavators from various brands and models at MyLittleSalesman.com. Compare prices, features, and locations of mini excavators for sale near you.Most Popular Mini Excavators Case Listings. 2018 Case CX57C $51,700 USD. 2015 Case .

0 · wheeled kinematic model

1 · kinematic model for wheeled platform

2 · 4 wheel skid steering robot

The S14 is a versatile stump grinder that can be mounted on mini skidsteers and mini excavators. It features round carbide teeth that can be rotated and replaced, and a heavy duty rotor that provides torque and RPM.

Figure 6 shows a summary of the tests done on marble surface with a symmetric mass distribution. The robot was driven using the speed pairs shown on Fig. 6a, corresponding to the whole motion range of the robot. Figure 6b shows the rotational speed of the robot measured with the IMU as well as the ones . See moreThe kinematic model was validated by adding weights sequentially either to the back (Figs. 4a, 5b, c), or to the sides of the robots (Figs. 4b, 5a), shifting the . See moreIn order to verify the assumption that wheels with more traction have minimum skid steer slip values (\(\Sigma _{SS}\)) Eq. 1 was calculated for the back wheels and . See moreIn order to asses the performance of the proposed kinematic model for dead reckoning scenarios indoor tests on a marble surface and outdoor tests both on . See more

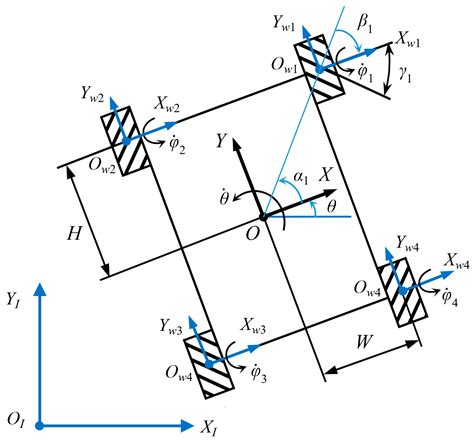

A mathematical model of a 4-wheel skid-steering mobile robot is presented in a systematic .In this section kinematic and dynamic model of four-wheel skid-steering mobile robot is .

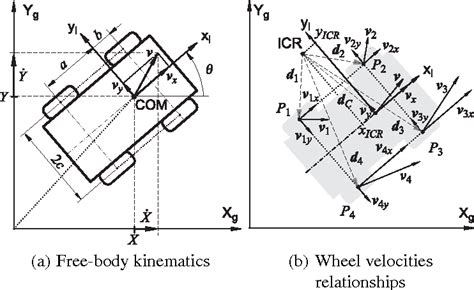

This article describes an improved kinematic model that takes these factors into account and verifies the model in a variety of working conditions, including different terrains and asymmetric loads, for two different wheeled skid-steered platforms.A mathematical model of a 4-wheel skid-steering mobile robot is presented in a systematic way. The robot is considered as a subsystem consisting of kinematic, dynamic and drive levels.

In this section kinematic and dynamic model of four-wheel skid-steering mobile robot is presented. We refer to the real experimental construction consists of two-wheel differentially driven mobile robots namely MiniTracker 3 (see Fig.1) [9]. In order to simplify the mathematical model of SSMR we assume that [2] plane motion is considered only, • A probabilistic motion model for SSWMRs capable of accurately estimating the distribution of robot positions and velocities in response to tire skid and slip. • A convex optimization formulation to combine the GP outputs from different terrains allowing the motion model to be used for diverse, potentially unseen terrains. To demonstrate the LG approach and its versatility and robustness, this paper develops an LG model representation of the dynamics of a four-wheel skid-steer mobile robot and verifies the accuracy by comparing the physical system and existing model provided in a popular robotics simulator (Gazebo).

This manuscript presents a comparison of mathematical models and non-complex artificial neural networks in energy prediction tasks for differential and skid-steer drive robots which move over various types of surfaces. In this work a novel method to adaptively identify the friction component of the dynamic model of skid-steered vehicles is proposed. The approach combines terramechanic-based and data driven models as a way to exploit the benefits of both modeling methodologies.Kinematic modeling of skid-steered platforms can be divided into two parts: the first is modeling their straight motion,andthesecondismodelingtheirrotations.Kinematic modeling of straight motion in terms of encoder readings is trivial, and due to reduced susceptibility of skid-steered platforms to slip during straight motion it is relatively mor.

The paper introduces mathematical models of a skid steered mobile platform for robotics. The platform consists of a rectangular steel construction with four wheels. Two banks of two drive wheels on each side are linked to two DC . This manuscript presents a comparison of mathematical models and non-complex artificial neural networks in energy prediction tasks for differential and skid-steer drive robots which move over various types of surfaces.

This article describes an improved kinematic model that takes these factors into account and verifies the model in a variety of working conditions, including different terrains and asymmetric loads, for two different wheeled skid-steered platforms.

A mathematical model of a 4-wheel skid-steering mobile robot is presented in a systematic way. The robot is considered as a subsystem consisting of kinematic, dynamic and drive levels.In this section kinematic and dynamic model of four-wheel skid-steering mobile robot is presented. We refer to the real experimental construction consists of two-wheel differentially driven mobile robots namely MiniTracker 3 (see Fig.1) [9]. In order to simplify the mathematical model of SSMR we assume that [2] plane motion is considered only, • A probabilistic motion model for SSWMRs capable of accurately estimating the distribution of robot positions and velocities in response to tire skid and slip. • A convex optimization formulation to combine the GP outputs from different terrains allowing the motion model to be used for diverse, potentially unseen terrains.

wheeled kinematic model

To demonstrate the LG approach and its versatility and robustness, this paper develops an LG model representation of the dynamics of a four-wheel skid-steer mobile robot and verifies the accuracy by comparing the physical system and existing model provided in a popular robotics simulator (Gazebo).

This manuscript presents a comparison of mathematical models and non-complex artificial neural networks in energy prediction tasks for differential and skid-steer drive robots which move over various types of surfaces. In this work a novel method to adaptively identify the friction component of the dynamic model of skid-steered vehicles is proposed. The approach combines terramechanic-based and data driven models as a way to exploit the benefits of both modeling methodologies.Kinematic modeling of skid-steered platforms can be divided into two parts: the first is modeling their straight motion,andthesecondismodelingtheirrotations.Kinematic modeling of straight motion in terms of encoder readings is trivial, and due to reduced susceptibility of skid-steered platforms to slip during straight motion it is relatively mor.

The paper introduces mathematical models of a skid steered mobile platform for robotics. The platform consists of a rectangular steel construction with four wheels. Two banks of two drive wheels on each side are linked to two DC .

kinematic model for wheeled platform

Mini excavator digging depth. In most cases, excavators in smaller construction sites are employed in trenches ranging from 1.5-meters up to 3.0-meters deep. So, a mini excavator that can dig to a 4.2-meter trench will benefit the majority of contractors exceptionally well. But, a depth of 2 meters is usually sufficient for the typical small .

mathematical model skid steer|4 wheel skid steering robot